Quality control poses a challenge in the production process of electronic manufacturing. It helps to indicate the proper implementation and compliance of a company to safety standards. In other words, quality control mainly contributes to your company in terms of risk management and product specifications.

For example, some smartphones have caused multiple incidents of battery explosions due to poor battery design and quality control. Also, some motor manufacturing companies have supplied inefficient motorcycle batteries caused by unregulated battery testing.

Remember, 80% of our industry depends on electronics and technology. As electronic designs become more complex, standards should be raised above than your market’s expectations.

Thus, you need to invest in Electronic Loads to ensure that your supplies are not only cost-effective but also promotes safety compliance and quality control.

What is an Electronic Load?

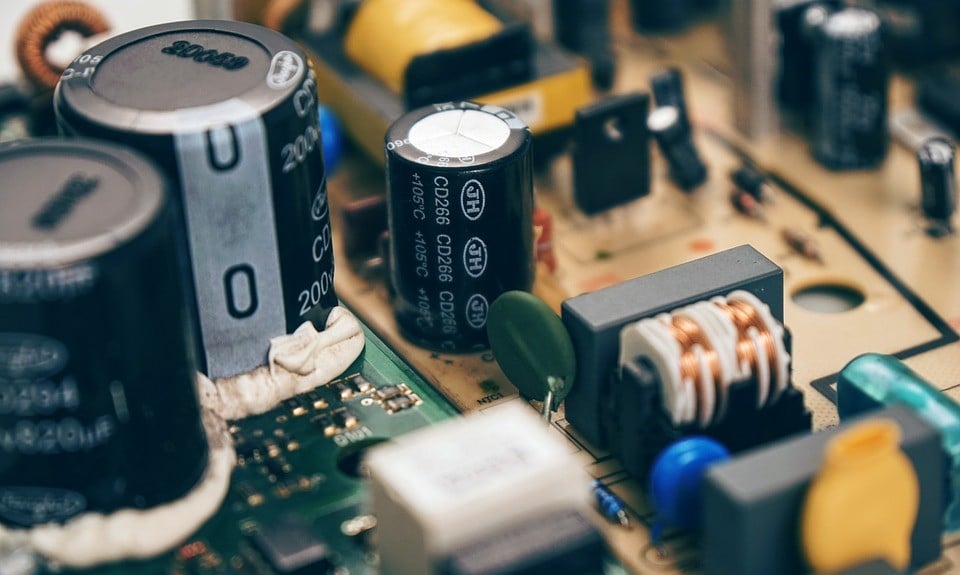

An electronic load or also known as “DC programmable load” is a type of instrument that is used to test power sources. It applies a voltage and sinks current to power supplies such as the motor battery, solar panel, and cellphone battery. It is commonly used by supply manufacturers by using oscilloscopes to test their products in checking the quality in compliance with the safety standards.

Moreover, an electronic load provides a load to the outputs of a power supply. The problem with real loads is complex and purely resistive. They are unpredictable and random in value. As a resolution, electronic load mimics real load to regulate and organize a fully controllable load.

In a sense, electronic loads are counterparts of power supplies. It means that they sink or absorb power while power supplies source power.

How Electronic Loads Work?

Electronic loads work in four modes either by Constant Voltage, Constant Current, Constant Constant Resistance, and Constant Power.

Constant Voltage mode (CV)

This first mode of electronic load maintains a constant voltage across the device under test. Commonly, this mode is used in testing battery charging circuits.

This mode allows a precision voltage divider to generate a feedback signal. Here, a voltage control amplifier compares the load’s input voltage against a reference signal. And the output of the input voltage turns to increase or decrease the RDS (resistance when the device is in saturation) on the power FET (field-effect transistor).

A perfect example of a Constant Voltage mode is a battery being charged in a constant current source.

Constant Current mode (CC)

This second mode sinks a current equal to the programmed current setting independently from the output voltage, which is typically forced by the voltage source. Its electronic load is loading the output of an external voltage source.

In this mode, the current amplifier compares the voltage on the current against a reference voltage and regulates its electronic load. It gives a difficult way to turn on the load FET. Power FET is used to manage the drain-to-source resistance.

Note that the circuit adjusts the gate voltage of the FET to add drain-to-resource resistance. In this way, it mitigates the current load.

Constant Resistance mode (CR)

In this third mode, the electronic load acts as a fixed programmable power resistor. Here, it is well-suited for loading a power source that is either a voltage or a current source.

When it senses its voltage at its input, it sinks proportionally to the input voltage. When the load connects to its source, its terminal voltage is equal to the imposed current multiplied by the programmed resistance value.

It is a perfect model to use in testing the capacity of a battery and to measure the start-up conditions of electronic devices.

Constant Power mode (CP)

This fourth mode, the load will attempt to work whatever load power is programmed. The electronic load uses whatever input voltage is given and adjusts current power what the user has set.

Constant Power mode measures the voltage across and current drawn by the load. It breaks up surface oxides and plating and varies current and voltage for consistent energy.

What are the Types of Electronic Loads?

The types of electronic loads depend on the different factors: load, demand, diversity, power, and utility of a system. Moreover, there are three major types of electronic loads: Resistive, Capacitive, and Inductive.

Resistive Load

A resistive load causes resistance in a wire producing friction and reduces the amount of current flow if the voltage remains constant. It produces heat and light as a result.

This type of electric load consumes electrical power, where the current wave remains in phase with the voltage wave. Resistive loads obstruct the flow of electrical energy in the circuit and convert it into thermal energy.

Examples of resistive loads are incandescent lamps and electric heaters.

Capacitive Loads

A capacitive load causes the voltage wave to lead the current wave. In other words, a capacitor can remain charged long without a voltage source.

The current is associated with capacitors in capacitive loads. It leads the voltage because it takes the dielectric material to charge up to full voltage from the charging current.

Capacitive loads are not similar to resistive loads and inductive loads, which can be purchased in retail. Power companies must first install capacitors regularly before a reactive power balance can work.

Inductive Loads

An inductive load operates through a magnetic field. It causes the current wave to lag the voltage wave. Thus, the power factor of an inductive load lags the applied voltage.

Inductive loads consume reactive powers. Any devices or equipment that have coils are inductive. Examples of inductive loads are contractor coils, compressors, speakers, relays, transformers, etc.

Key Takeaways

Electronic loads help your company in terms of quality control and safety standards. It is a type of instrument that is used to test power sources. It applies a voltage and sinks current to power supplies such as the motor battery, solar panel, and cellphone battery.

It has four modes, namely Constant Voltage mode, Constant Current mode, Constant Resistance mode, and Constant Power mode. Moreover, there are three types of electronic loads, including Resistive load, Capacitive load, and Inductive load.

Ultimately, gone are the days that poor battery designs and unregulated quality control affect your company’s reputation. By investing in Electronic Loads, it ensures that your supplies are not only cost-effective but also promotes safety compliance and quality control.